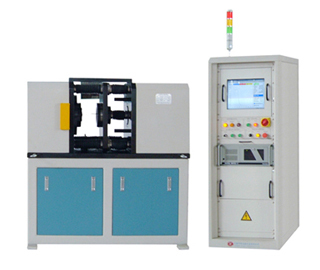

Test Bench To Detect Drag on Clutch Disc Assembly

Main Features

* It mainly consists of basic machine , measuring system and servo-motor control system.

* Adopting DC speed regulating motor to apply a torque to disc assembly in one side, and that doing servo-motor,

gear box, ball screw to load in another side. Its feature is that to assure accuracy stopped for displacement. The

displacement can be stopped in optional setting position, its accuracy can reach 0.01mm.

* The torque transducer is used to test torque value, and that displacement sensor in axis direction to measure a

variation of displacement of workpiece in moving back process with its fixture.

* Separately to select “definite torque method” and “definite displacement method” in test, to make

measurement.

* Windows operation system, data base function, high accuracy measuring card.

* All measuring results can be stored for query, and its curve displayed on the screen, and to print on A4 paper if

need.

Testing Items

* Free movement

* Drag torque

* Axial pressure

* Free thickness

* Clamping thickness

* Drag torque- free movement curve

Technical Data

|

Product type

|

|

ZL-CTY240SJ

|

ZL-CTY330SJ

|

ZL-CTY430SJ

|

ZL-CTY430SJT

|

|

Range of disc assembly

|

mm

|

φ160-φ240

|

φ240-φ330

|

φ330-φ430

|

φ180-φ430

|

|

Max. torque

|

N·m

|

5

|

5

|

10

|

10

|

|

Max. clamp load

|

kN

|

10

|

20

|

40

|

40

|

|

Measuring accuracy of free movement

|

mm

|

0.02

|

0.03

|

0.05

|

0.05

|

|

Measuring accuracy of drag torque

|

% F.S

|

±0.5

|

±0.5

|

±0.5

|

±0.5

|

|

Dimension

|

mm

|

1200×550×1650

|

1200×550×1650

|

1250×600×1650

|

1250×600×1650

|

|

Weight (gross)

|

kg

|

600

|

600

|

800

|

800

|